Book Appointment Now

Key Technologies Used by Marine Dredging Contractors for Deep-Water Projects

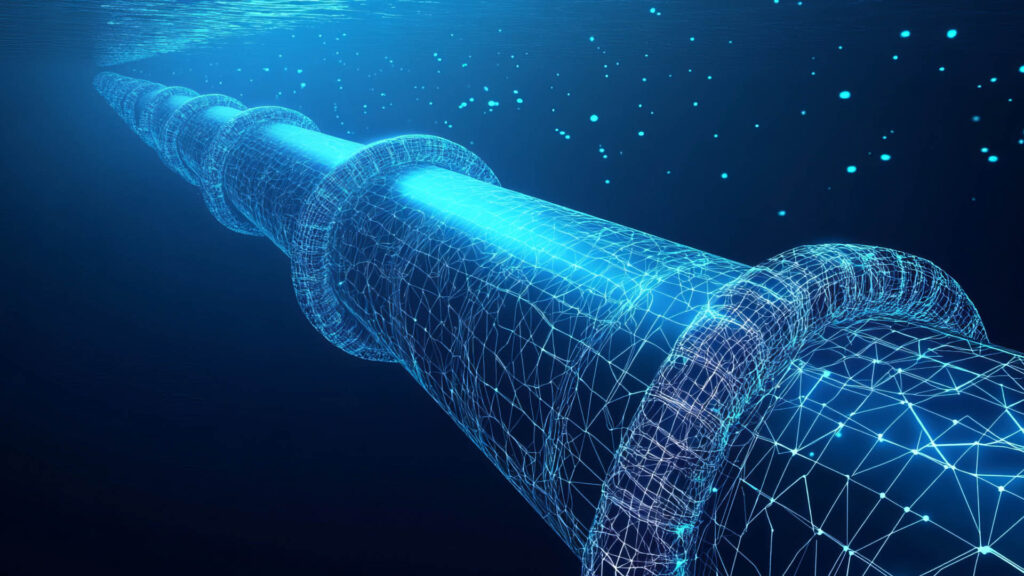

Marine dredging contractors play a critical role in sediment management by ensuring efficient material transport through well-designed pipeline systems. Dredging operations rely on a combination of powerful suction pumps, discharge pipelines, and booster stations to move sediment from excavation sites to designated disposal or reclamation areas. Without a properly managed pipeline transport system, dredging projects can face challenges such as blockages, reduced efficiency, and increased operational costs.

In marine dredging, pipeline design is essential for maintaining a steady flow of sediment and preventing clogging. Factors such as pipeline diameter, material composition, and layout impact dredging efficiency. Properly designed transport systems help mitigate sediment buildup, minimize equipment wear, and ensure uninterrupted operations. The challenge in lake dredging is managing sediment removal without disrupting the aquatic ecosystem. Lakes often require specialized pipeline configurations that reduce turbidity and prevent excessive sediment resuspension.

Advancements in dredging technology have further improved sediment transport. Automated monitoring systems, GPS integration, and AI-driven flow optimization are now helping marine dredging contractors enhance pipeline efficiency. Whether working on large-scale offshore projects or small-scale lake dredging operations, the right pipeline management strategies ensure that dredging remains productive, cost-effective, and environmentally responsible.

Understanding Pipeline Transport in Marine Dredging

Pipeline transport is a crucial component of marine dredging operations, enabling the movement of large volumes of sediment over long distances. Marine dredging contractors rely on well-designed pipeline systems to transport slurry efficiently from dredging sites to disposal or reclamation areas. These pipelines are engineered to handle various sediment types, flow conditions, and operational challenges, ensuring that dredging remains productive and cost-effective.

Key Components of a Dredging Pipeline System

- Suction Pipeline – Connected to the dredging vessel, the suction pipeline draws in water and sediment through the cutter head or suction intake.

- Discharge Pipeline – This pipeline transports the dredged material from the dredger to the disposal or reclamation site. Its diameter and length impact flow efficiency.

- Booster Pumps—Used in long-distance dredging projects, booster pumps maintain consistent pressure to prevent blockages and sediment settling.

- Slurry Transport systems manage the flow of the dredged material, ensuring it remains fluid for smooth transport.

Factors Influencing the Sediment Movement

The efficiency of sediment transport depends on several factors:

- Flow Velocity – Maintaining the right velocity prevents sediment from settling and blocking the pipeline.

- Material Composition – Coarse sediments require higher flow energy, while fine sediments in lake dredging operations need careful handling to minimize turbidity.

- Transport Distance – Longer pipelines require additional booster pumps to sustain flow and pressure.

By optimizing these factors, marine dredging contractors can ensure smooth and uninterrupted sediment transport. Proper pipeline management is essential for maximizing efficiency and reducing maintenance costs, whether working on offshore projects or lake dredging.

2. Common Challenges in Pipeline Transport

Efficient pipeline transport is essential for successful dredging operations, but marine dredging contractors often face several challenges that can reduce efficiency, increase costs, and cause project delays. Understanding these challenges and implementing proactive solutions ensures smoother sediment transport and minimizes operational disruptions.

Blockages and Pipeline Clogging

One of the most significant challenges in dredging pipeline transport is blockages caused by sediment buildup. If flow velocity drops too low, heavier materials settle within the pipeline, reducing transport capacity and causing system failure. Marine dredging contractors must carefully monitor pressure and flow rates to prevent such obstructions. Booster pumps and optimized pipeline design play a crucial role in maintaining steady sediment movement.

Sediment Settling and Flow Velocity

For dredging pipelines to function effectively, they must maintain a consistent velocity to keep sediment suspended. In lake dredging projects, where water flow is relatively still, maintaining this flow can be challenging. Without proper velocity control, sediment can settle prematurely, leading to inefficient operations and increased maintenance.

Wear and Tear on Pipelines

Pipelines endure significant abrasion from the continuous flow of sand, silt, and debris. This is especially true in open-water and lake dredging, where shifting materials accelerate wear. Using wear-resistant pipeline materials and implementing routine inspections help mitigate these issues.

Managing Different Sediment Types

Coarse materials like gravel require stronger suction power and higher transport energy, while fine-grained sediments can increase turbidity. Marine dredging contractors must select the right equipment and pumping configurations to handle varying sediment types efficiently.

3. Optimizing Pump and Pipeline Performance

For marine dredging contractors, optimizing pump and pipeline performance is crucial for ensuring efficient sediment transport and preventing costly delays. Selecting the right dredge pumps, configuring the pipeline properly, and maintaining optimal flow conditions help improve dredging efficiency in both offshore and lake dredging projects.

Selecting the Right Dredge Pumps

Choosing the appropriate pump depends on the type of sediment, transport distance, and project scale. Marine dredging contractors working in deep waters or handling coarse materials require high-powered dredge pumps with reinforced impellers. In lake dredging, where finer sediments are common, pumps with precision flow control minimize turbidity and environmental disturbance.

Impeller Design, Pump Speed, and Pressure Control

The impeller design affects sediment transport efficiency. A properly designed impeller ensures smooth flow, reduces clogging, and maximizes pump longevity. Adjustable pump speed and pressure control help maintain consistent sediment movement. If the speed is too low, sediment settles and causes blockages; too high, it leads to excessive wear on the pipeline and pump components.

Use of Booster Pumps for Long-Distance Dredging

Booster pumps help maintain pressure and prevent sediment buildup in projects requiring extended pipelines. Marine dredging contractors often incorporate booster stations in long-distance dredging to ensure uninterrupted sediment transport.

Best Practices for Preventing Blockages

Maintaining proper flow velocity, monitoring pressure changes, and implementing real-time diagnostics help prevent blockages. In lake dredging, operators must carefully manage suction rates and discharge flow to avoid excess sediment settling. By optimizing pump and pipeline performance, dredging projects can achieve greater efficiency and reduced operational costs.

4. Effective Pipeline Design and Configuration

Proper pipeline design is essential for ensuring the smooth and efficient transport of sediment in marine dredging and lake dredging operations. Marine dredging contractors must carefully consider factors such as pipeline length, diameter, material composition, and layout to optimize flow efficiency while reducing wear and maintenance costs.

Determining the Ideal Pipeline Length and Diameter

Pipeline length and diameter significantly impact dredging efficiency. Longer pipelines require more energy to maintain sediment movement, often necessitating booster pumps to sustain pressure and prevent blockages. If the pipeline diameter is too small, friction loss increases, reducing flow rates and increasing energy consumption. Conversely, oversized pipelines can lead to sediment settling. Marine dredging contractors must balance these factors to ensure consistent and efficient material transport, especially in long-distance offshore dredging and lake dredging projects.

Impact of Bends, Curves, and Pipeline Layout on Flow Efficiency

Pipeline configuration plays a critical role in maintaining an uninterrupted flow of sediment. Sharp bends, abrupt turns, and unnecessary curves create turbulence and pressure drops, increasing the risk of clogging. Designing pipelines with smooth, gradual curves helps minimize resistance and ensures a steady slurry movement. Marine dredging contractors should strategically plan layouts to reduce energy loss and extend equipment lifespan.

Best Materials for Reducing Wear and Extending Pipeline Lifespan

Due to continuous exposure to sediment and water flow, pipelines experience significant abrasion. To enhance durability, high-density polyethylene (HDPE), rubber-lined steel, and composite materials are commonly used. Wear-resistant materials reduce maintenance needs and increase operational efficiency in marine and lake dredging environments.

5. Advanced Technologies for Efficient Pipeline Transport

The integration of modern technologies has transformed marine dredging operations, improving sediment transport efficiency and reducing maintenance costs. Marine dredging contractors are increasingly adopting automation, AI-driven predictive maintenance, and GPS-based tracking systems to optimize pipeline transport. These advancements help ensure steady material flow, prevent blockages, and enhance overall project performance, whether in offshore dredging or lake dredging projects.

Use of Automation and Real-Time Monitoring

Automation plays a vital role in optimizing sediment transport. Sensors embedded in dredging pipelines continuously monitor flow rates, pressure levels, and sediment concentration. Real-time data enables operators to make immediate adjustments, preventing blockages and improving efficiency. Automated control systems also allow marine dredging contractors to remotely manage dredging operations remotely, reducing the need for manual oversight.

AI-Driven Predictive Maintenance

Artificial intelligence (AI) is revolutionizing maintenance strategies in marine dredging. AI-powered predictive maintenance uses historical data and real-time monitoring to detect potential failures before they occur. By analyzing trends in pump performance and pipeline conditions, dredging teams can schedule preventive maintenance, minimizing downtime and costly repairs. This technology is particularly useful in lake dredging, where maintaining consistent sediment flow is essential to avoid environmental disruption.

GPS Integration for Dredging Efficiency

GPS-based tracking systems allow operators to monitor dredging activities and material transport precisely. By mapping dredging zones, marine dredging contractors can optimize excavation patterns, ensure even material distribution, and enhance project accuracy.

Future Innovations in Sediment Transport

New materials, including reinforced composites and self-cleaning coatings, are being developed to reduce pipeline wear and extend operational life. Sustainable sediment management solutions will further improve efficiency and environmental responsibility in both offshore and lake dredging projects.

6. Environmental Considerations and Sustainable Dredging Practices

Pipeline dredging plays a crucial role in maintaining waterways, but it also has significant environmental implications. In both lake dredging and coastal dredging projects, sediment transport can impact aquatic ecosystems by altering water quality, disturbing habitats, and increasing turbidity. Marine dredging contractors must implement sustainable practices to minimize these effects while maintaining dredging efficiency.

The Impact of Pipeline Dredging on Aquatic Ecosystems

Dredging pipelines transport large volumes of sediment, which can lead to turbidity and sediment resuspension. In lake dredging, excessive turbidity can reduce oxygen levels, harm fish populations, and disrupt plant growth. Similarly, coastal dredging can affect coral reefs, marine life, and shoreline stability. Careful monitoring and controlled sediment release help mitigate these impacts.

Best Practices for Minimizing Turbidity and Sediment Resuspension

- Using silt curtains and turbidity barriers to contain disturbed sediment.

- Optimizing dredge pump settings to control sediment movement.

- Implementing real-time monitoring to adjust operations based on environmental conditions.

Compliance with Environmental Regulations and Sustainable Materials

Governments and environmental agencies impose strict guidelines on lake dredging and offshore dredging projects to protect ecosystems. Marine dredging contractors must comply with regulations on sediment disposal, water quality, and protected habitats. The use of eco-friendly pipeline materials, such as biodegradable polymers and reinforced composites, is gaining traction to reduce environmental impact.

Adoption of Eco-Friendly Technologies

Modern dredging techniques now incorporate electric and hybrid-powered dredgers, low-impact suction technologies, and sediment recycling initiatives. By adopting sustainable dredging practices, marine dredging contractors can balance operational efficiency with environmental responsibility, ensuring long-term viability for both industry and ecosystems.

Conclusion

Optimizing pipeline transport in marine dredging requires a combination of strategic planning, advanced equipment, and real-time monitoring. Efficient sediment movement depends on selecting the right dredge pumps, designing pipelines to minimize blockages, and integrating automation for improved performance. By implementing best practices such as optimizing flow velocity, using booster pumps, and selecting durable pipeline materials, dredging operations can enhance efficiency and reduce maintenance costs.

For lake dredging and offshore projects, environmental responsibility is just as important as operational efficiency. Sustainable dredging practices, including turbidity control, eco-friendly pipeline materials, and compliance with environmental regulations, help minimize the impact on aquatic ecosystems. Incorporating AI-driven predictive maintenance and GPS-guided dredging further improves project accuracy and resource management.

Marine dredging contractors must invest in modern dredging solutions that increase efficiency while protecting the environment. Real-time monitoring, automation, and energy-efficient dredging equipment allow for smarter, more sustainable operations. By adopting these advancements, marine dredging contractors can ensure long-term success, reduce operational risks, and contribute to environmentally responsible sediment management in lake dredging and marine projects.