Book Appointment Now

Key Benefits of Using Variable Frequency Drive Pumps in Industry

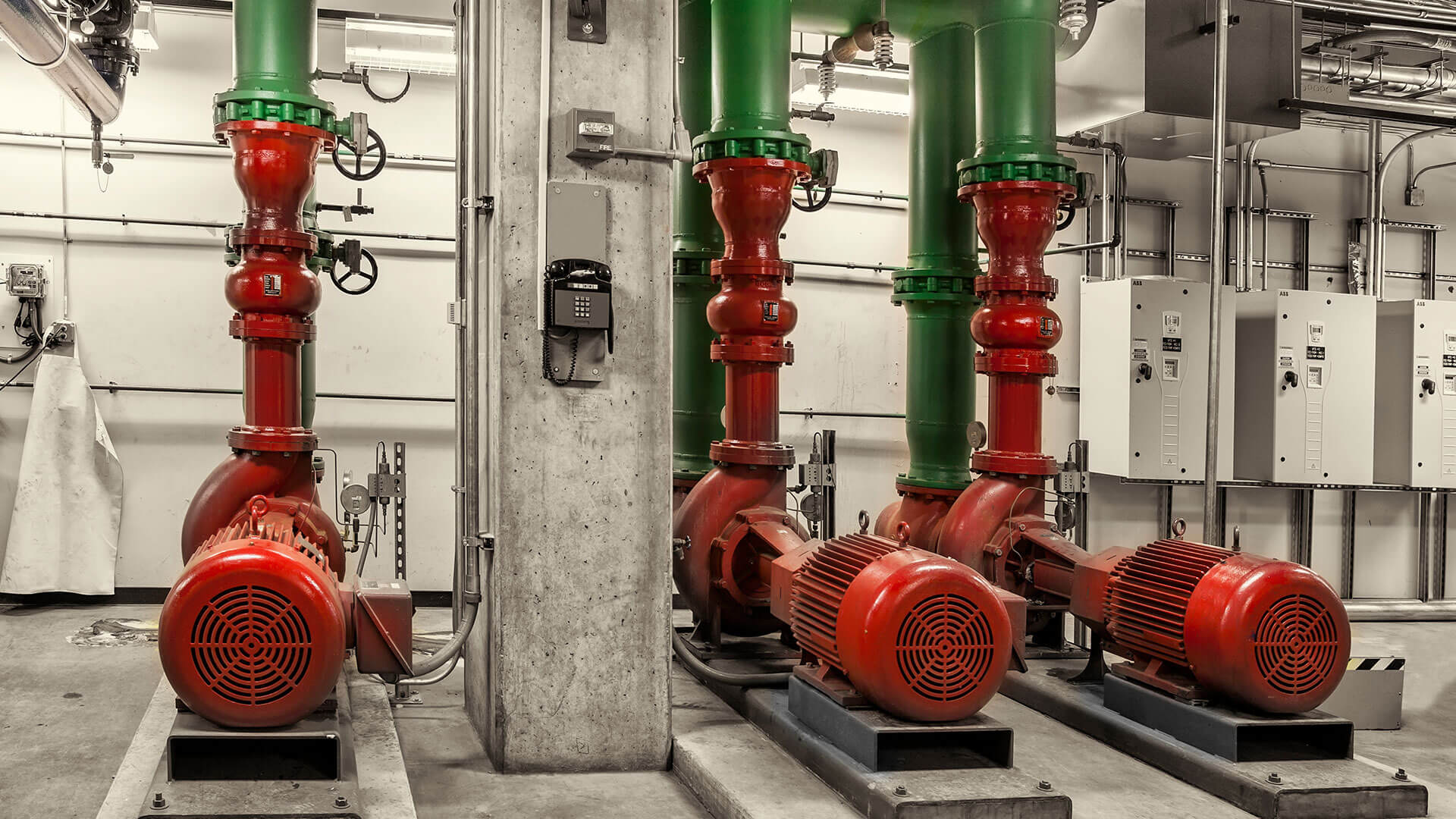

In today’s industrial landscape, energy efficiency, process optimization, and equipment longevity are top priorities for many sectors. One technology that has proven invaluable in achieving these goals is the variable frequency drive pump. VFD pumps offer significant advantages over traditional fixed-speed pumps, especially in industries that require precise control of fluid movement, such as water treatment, mining, oil and gas, and construction.

The goal of this blog is to explore the key benefits of variable frequency drive pumps, with a particular focus on their ability to drive energy savings, enhance process optimization, and reduce equipment wear. These pumps are revolutionizing how industrial systems operate, providing enhanced performance, efficiency, and long-term cost reductions.

What is a Variable Frequency Drive (VFD) Pump?

A variable frequency drive pump is a type of pump that uses a variable frequency drive to control the speed and operation of its motor. The VFD adjusts the electrical frequency supplied to the pump’s motor, allowing it to operate at varying speeds. This adaptability helps match pump output to the specific needs of the system, optimizing energy consumption and ensuring efficient performance across a range of industrial applications.

The primary components of a variable frequency drive pump include the motor, the drive, and the controller:

- Motor: The pump motor, which powers the pump impeller, is designed to work efficiently with varying speeds, as controlled by the VFD.

- Drive: The drive is responsible for controlling the frequency and voltage supplied to the motor, thus regulating its speed. By adjusting the speed of the motor, the VFD allows the pump to operate more efficiently, depending on real-time demands.

- Controller: The controller monitors system conditions, such as pressure, flow, and temperature, and adjusts the speed of the pump to optimize performance and energy use.

The use of VFD pumps has become increasingly important in modern industrial pump systems. Unlike traditional pumps that operate at a fixed speed, variable frequency drive pumps provide superior flexibility, allowing industries to adjust pump speeds based on specific system requirements. This capability makes them particularly valuable in applications where energy savings, precise control, and minimal equipment wear are crucial.

By offering dynamic control over pump operation, VFD pumps are transforming industrial operations across diverse sectors. Whether in water treatment plants, mining operations, or manufacturing facilities, the ability to regulate the pump speed ensures that energy is used efficiently, equipment is protected from wear and tear, and processes remain optimized.

Core Benefits of VFD Pumps

Energy Savings

One of the most significant advantages of a variable frequency drive pump is its ability to optimize energy consumption. By adjusting the motor speed to match the specific load demands, VFD pumps ensure that energy is used only when and where it’s needed. Unlike traditional fixed-speed pumps, which run at full capacity regardless of system demand, VFD pumps operate at variable speeds, delivering energy savings that can reach up to 40% or more.

In industries like water treatment, where pumps often run continuously at varying loads, variable frequency drive pumps can dramatically reduce electricity consumption. For example, a VFD pump controlling flow rates in a municipal water treatment plant can adjust the motor speed based on the volume of water being processed, thus avoiding the waste of energy when the system demand is low. Similarly, in the mining sector, VFD pumps used in slurry pumping can optimize the motor speed to reduce energy consumption while maintaining the required flow and pressure levels, especially during periods of lower operational demand.

Reduced Peak Energy Demand

Another key benefit of VFD pumps is their ability to reduce peak energy demand. Traditional pumps often draw a large surge of power when starting up, known as inrush current, which can significantly spike electricity usage during peak demand periods. However, variable frequency drive pumps mitigate this issue by soft-starting the motor, gradually ramping up to the desired speed, and reducing the initial power surge.

This capability not only lowers energy consumption but also reduces overall utility costs. For instance, in manufacturing facilities, where energy costs can be high during peak hours, using a VFD pump can help flatten demand curves, resulting in more consistent energy consumption and lower electricity bills. Similarly, in HVAC systems, VFD pumps can optimize fan and pump speeds based on system load, avoiding unnecessary energy use during periods of low demand, thus contributing to cost savings.

Equipment Protection

A variable frequency drive pump also plays a critical role in protecting pump and motor components from excessive mechanical stress. By controlling the acceleration and deceleration rates, VFD pumps prevent sudden starts and stops, which can place undue strain on the pump components, leading to premature wear. This soft-start feature is particularly beneficial in environments where pumps frequently start and stop, as it reduces the risk of damaging bearings, seals, and impellers.

As a result, VFD pumps extend the lifespan of pumps and motors, minimizing the need for costly repairs and replacements. In sectors such as oil and gas or water treatment, where pumps are essential for continuous operations, ensuring the longevity of the equipment is paramount. By reducing mechanical stress and thermal strain, VFD pumps help maintain optimal pump performance and reliability over extended periods.

Process Control and Flexibility

Variable frequency drive pumps provide exceptional process control and flexibility, allowing industries to adjust pump speed in real-time to meet specific operational needs. The ability to fine-tune pump speeds enables better optimization of flow rates and pressures, which is particularly valuable in applications that require precise control, such as chemical processing, mining, and construction.

In chemical processing, for example, a VFD pump can be adjusted to ensure that the flow of chemicals is controlled accurately, preventing over-pumping and minimizing waste. Similarly, in mining, VFD pumps allow for more efficient dewatering and slurry pumping, adjusting motor speeds based on the viscosity and volume of the material being pumped. The flexibility to adapt to varying conditions not only improves efficiency but also enhances system performance, ensuring that operations are running smoothly even under changing conditions.

Lower Maintenance Costs

A major advantage of VFD pumps is the reduction in maintenance requirements. By controlling motor speed and reducing mechanical stresses, VFD pumps experience less wear and tear, which translates into fewer maintenance needs. Additionally, VFD pumps often come equipped with built-in diagnostic tools that help detect potential issues before they result in equipment failure, further reducing downtime and repair costs.

In industries like oil and gas, where the cost of downtime can be significant, variable frequency drive pumps help ensure continuous operations by minimizing unplanned maintenance events. Similarly, in water treatment, where pump reliability is critical, VFD pumps help reduce the frequency and cost of repairs by maintaining a steady operational environment. Over the long term, this leads to substantial savings on both maintenance and replacement parts, making VFD pumps a cost-effective solution for industrial pump systems.

VFD Pumps in Industrial Pump Systems

Optimized Flow and Pressure

One of the key benefits of a variable frequency drive pump is its ability to dynamically adjust flow and pressure to meet real-time demands. This flexibility ensures optimal performance and efficiency across various industrial applications. Unlike traditional fixed-speed pumps that operate at a constant speed regardless of the system requirements, VFD pumps can adjust their speed to align with varying operational needs, improving overall system efficiency.

For instance, in irrigation systems, a VFD pump can regulate water flow to match specific crop watering schedules or changing weather conditions. This level of control ensures that energy is only used when needed, preventing unnecessary waste. In water treatment, VFD pumps help maintain consistent flow rates while responding to fluctuating water quality or volume, providing precise dosing and preventing system overload. Similarly, in slurry handling, VFD pumps adjust the motor speed to optimize the flow of slurry, preventing over-pumping and ensuring that the system operates efficiently.

Extended Pump Life

Variable frequency drive pumps are designed to run at variable speeds, which helps to reduce the operational strain on pump components. By adjusting motor speeds to meet specific load demands, VFD pumps operate at lower speeds when full capacity is not needed. This reduction in speed significantly decreases wear and tear on critical pump components, such as impellers, seals, and bearings.

For heavy industries like mining or oil and gas, where pumps are subjected to harsh operating conditions, this extended operational life can lead to fewer repairs and lower maintenance costs. By maintaining optimal performance without pushing the pump to its maximum capacity, VFD pumps help protect vital parts, ensuring that the system runs smoothly for longer periods and reducing the frequency of component replacements.

Minimized Hydraulic Losses

VFD pumps are particularly effective in minimizing hydraulic losses, an essential factor in optimizing system efficiency. Traditional pumps often operate at constant speeds, which can result in over-pumping or under-pumping, causing inefficient energy use and increased wear. However, with a variable frequency drive pump, the motor speed is adjusted in real-time, ensuring that the pump operates only at the speed required to meet system demands.

By avoiding over-pumping, VFD pumps reduce the risk of energy waste, ensuring that the system operates within its optimal range. This not only leads to energy savings but also improves overall system performance, particularly in complex processes like slurry pumping and water treatment.

Reduced Water Hammer

Water hammer, or pressure surges, is a common issue in traditional pump systems that can lead to significant damage to infrastructure, pipes, and pump components. Variable frequency drive pumps (VFD pumps) are designed with soft-start and soft-stop features that help reduce these pressure surges. By gradually accelerating and decelerating the motor speed, VFD pumps minimize the sudden pressure changes that typically occur during startup or shutdown.

This feature is crucial in industries such as water treatment and mining, where pressure surges can lead to costly infrastructure damage and system downtime. With VFD pumps, the gradual change in speed helps maintain consistent pressure levels, preventing water hammer and ensuring that both the pump and its associated infrastructure are protected from excessive stress.

Real-World Industrial Applications of VFD Pumps

Water Treatment and Dredging

In water treatment and dredging operations, variable frequency drive pumps play a crucial role in managing variable flow rates and enhancing operational efficiency. In water treatment plants, VFD pumps adjust to fluctuations in water demand and quality, optimizing energy use while maintaining consistent flow and pressure. This flexibility is essential for efficiently handling the treatment process, from filtration to chemical dosing, reducing energy costs, and ensuring that water quality standards are met.

In dredging, VFD pumps are used to control the flow of slurry and water, enabling operators to optimize pump speed based on material density and water conditions. By adjusting the pump speed dynamically, VFD pumps reduce energy consumption and ensure efficient dredging operations, whether in coastal, river, or harbor environments. This adaptability is especially valuable in dredging projects where the flow rate requirements can vary greatly depending on the nature of the material being pumped.

Mining

In the mining industry, VFD pumps are essential for handling slurry and dewatering systems. These pumps are typically used in challenging environments where conditions can vary widely. Variable frequency drive pumps adjust to different flow rates and pressures, ensuring optimal performance while reducing energy consumption. The ability to match motor speed to load demand helps lower operating costs and improve the overall efficiency of slurry pumps, which are critical for handling heavy, viscous materials.

Moreover, VFD pumps offer enhanced reliability in harsh mining environments, where consistent performance is essential. In dewatering systems, VFD pumps help maintain the necessary flow rates for groundwater removal, ensuring that mining operations run smoothly and that the risk of downtime is minimized.

Chemical Processing

Variable frequency drive pumps are widely used in chemical processing to optimize the rates and pressures is critical for maintaining safety standards and ensuring that chemicals are handled correctly. VFD pumps provide the flexibility to adjust motor speeds based on the specific requirements of each process, improving energy efficiency and reducing waste.

For example, VFD pumps can control the flow of chemicals during mixing and dosing operations, ensuring that precise amounts are delivered at the required pressure and flow rate. This control not only enhances the safety and efficiency of chemical processes but also helps to reduce overall energy consumption, making VFD pumps a valuable asset in the chemical processing industry.

Construction

On construction sites, VFD pumps are used to regulate water supply, dewatering, and mixing equipment, improving the efficiency and management of resources. During construction projects, especially in areas prone to flooding or with high groundwater tables, VFD pumps help manage water removal efficiently. By adjusting the pump speeds based on real-time water levels, VFD pumps ensure that the right amount of water is pumped at any given time, avoiding both over-pumping and under-pumping.

In addition, VFD pumps are used in concrete mixing and other construction processes, where they help control the flow of materials and water to improve consistency and quality. This dynamic control helps reduce energy consumption and enhances operational efficiency, contributing to the overall success of construction projects.

Food and Beverage

In the food and beverage industry, variable frequency drive pumps are used to enhance precision in conveying, mixing, and refrigeration processes. Whether transporting liquids, mixing ingredients, or controlling refrigeration systems, the ability to adjust pump speeds ensures that operations are carried out with accuracy and efficiency. For example, in a bottling facility, VFD pumps control the flow of liquids during filling processes, maintaining consistent pressure and speed to prevent overflows and optimize production rates.

Moreover, VFD pumps help regulate temperatures in refrigeration systems by controlling the flow of refrigerants, ensuring energy-efficient operation and consistent product quality. By enabling precise control over various stages of production, VFD pumps not only improve energy efficiency but also contribute to better product consistency and quality.

HVAC and Cooling

In HVAC systems and cooling towers, VFD pumps are used to control the speeds of pumps and fans, improving climate management across commercial and industrial buildings. VFD pumps in HVAC systems adjust airflow and water circulation based on real-time temperature and pressure readings, ensuring that the system operates efficiently while maintaining the desired climate conditions.

By regulating the speed of pumps and fans, VFD pumps help reduce energy consumption during periods of lower demand, such as at night or during off-peak hours. This dynamic control not only helps lower operational costs but also extends the lifespan of HVAC equipment by reducing wear and tear on components. In cooling towers, VFD pumps ensure that water is circulated efficiently, improving cooling capacity and reducing energy consumption, making them a valuable tool for climate management in large facilities.

Benefits of VFDs for Well Pumps

Consistent Water Pressure

Variable frequency drive pumps are ideal for maintaining stable water pressure in well systems. Unlike traditional pumps that operate at a fixed speed, VFD pumps adjust motor speed based on real-time water demand, ensuring consistent pressure. This ability to dynamically control flow rates prevents fluctuations in pressure, which can occur during periods of high or low water usage. In well systems, where pressure stability is critical for efficient water supply management, VFD pumps provide the necessary control to ensure that water is delivered consistently to the system, whether it’s for residential, agricultural, or industrial use.

Improved Energy Efficiency

One of the key advantages of a variable frequency drive pump in well systems is its ability to operate efficiently during low-demand periods. Rather than running at full capacity constantly, VFD pumps adjust their speed to match the actual water usage, ensuring that the motor only consumes energy when needed. This results in significant energy savings, especially in systems that experience varying water demand throughout the day or year. In areas where water demand fluctuates, the energy-efficient operation of VFD pumps helps reduce operational costs, making them a cost-effective solution for well pumping systems.

Reduced Wear and Tear

VFD pumps play a crucial role in minimizing wear and tear on well pump components. Traditional well pumps often cycle on and off or run at a constant high speed, causing stress on motor components and leading to more frequent repairs. However, VFD pumps reduce the frequency of motor cycling by adjusting the speed based on the system’s water demand. This gradual change in speed helps to minimize the mechanical stress on components like bearings, seals, and the motor itself, leading to longer lifespans for the pump and reducing the need for costly repairs or replacements. The reduced wear on components makes VFD pumps a valuable investment in well systems that require long-term, reliable operation.

Quiet Operation

Another notable benefit of variable frequency drive pumps is their quieter operation compared to traditional pumps. The ability of VFD pumps to gradually adjust motor speeds means that they start and stop more smoothly, reducing the noise typically associated with abrupt pump startups and shutdowns. This makes VFD pumps especially advantageous in residential areas or other occupied spaces where noise levels need to be kept to a minimum. In addition, the ability to adjust the pump speed based on demand ensures that the pump runs at lower speeds when possible, further reducing operational noise while maintaining the necessary water pressure and flow. This quiet operation enhances the overall user experience, particularly in settings where noise is a concern.

Conclusion

Variable frequency drive pumps offer a wide range of benefits that can significantly improve the performance and efficiency of industrial pump systems. From optimizing energy consumption and reducing peak demand to enhancing process control and extending equipment lifespan, the advantages of VFD pumps are evident across various industries. By providing precise control over flow rates, pressures, and motor speeds, VFD pumps contribute to more efficient operations, reduced maintenance costs, and long-term cost savings.

For procurement heads, engineering managers, and decision-makers, integrating VFD technology into your industrial systems presents a strategic opportunity to enhance operational efficiency, lower energy costs, and prolong the life of critical equipment. With real-world applications spanning from water treatment and mining to HVAC and well pumping, the potential for improved system performance is vast.

By embracing variable frequency drive pumps, your organization can achieve optimized performance while reducing overall costs and ensuring that equipment operates reliably for years to come. Consider the integration of VFD technology today to realize these significant benefits and stay ahead in a competitive industry.