Book Appointment Now

Innovations in Cable‑Deployed and Autonomous Dredging in Pakistan

Keeping waterways operational in Pakistan is a constant challenge. Rivers carry heavy sediment loads, tidal zones shift quickly, and port channels lose depth faster than scheduled dredging cycles can keep up. For port operators and contractors, dredging is not a one-time capital project. It is ongoing maintenance work that must be planned around budget constraints, access limitations, and tight operating windows across Pakistan waterways.

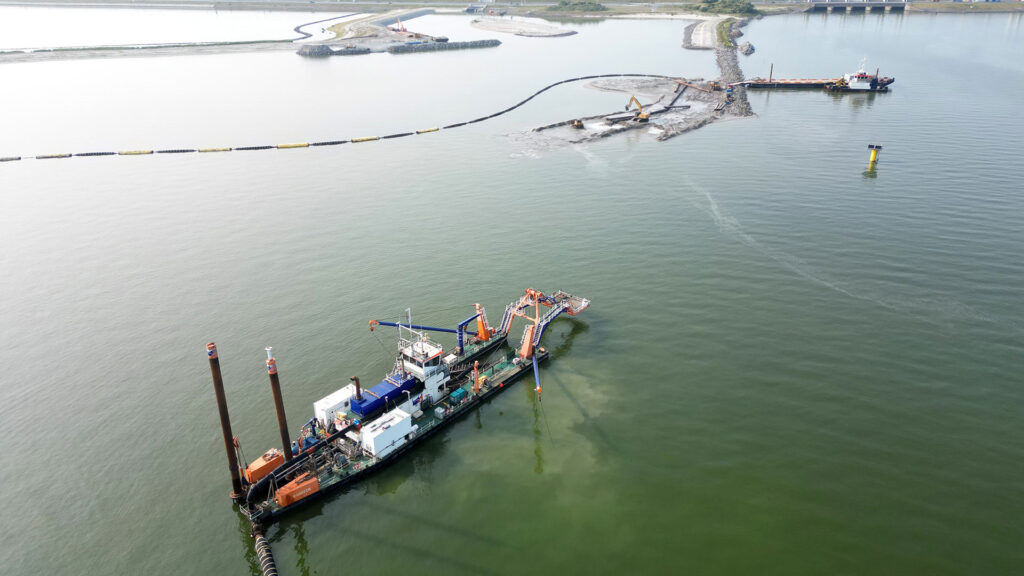

In this context, cable-deployed dredging is gaining attention because it aligns with how maintenance dredging is actually performed on the ground. These systems can be deployed from shore or simple pontoons, require less mobilisation time, and offer better control in narrow or shallow areas where large dredgers are inefficient. As automation is introduced into pumping, positioning, and monitoring, autonomous dredging is enabling more consistent output with fewer operational variables.

Hydro Pump and Dredge work within this reality. The company supplies dredge pumps, slurry-handling systems, and Anaconda hoses for cable-deployed dredging configurations designed for continuous operation. Instead of focusing on oversized equipment, the approach supports practical dredging setups that match the scale, frequency, and constraints of maintenance work across Pakistan waterways.

Why Pakistan waterways need next-generation dredging now

Dredging demand in Pakistan is not increasing because of expansion alone. It is increasing because existing waterways are harder to maintain with conventional approaches. Sediment loads from the Indus river system remain high, monsoon cycles are becoming less predictable, and vessel sizes calling at major ports continue to grow. Together, these factors shorten the interval between dredging cycles across Pakistan waterways.

For many operators, the issue is not access to dredging equipment. It is a mismatch. Large hopper dredgers are expensive to mobilise and inefficient for routine maintenance in confined channels, berths, and river sections. Smaller mechanical dredgers often struggle with consistency, depth accuracy, and slurry transport over distance. The result is frequent rework, higher fuel consumption, and downtime that affects port operations.

This is where cable-deployed dredging starts to make operational sense. Maintenance dredging requires systems that can be mobilised quickly, operate within limited footprints, and run for extended periods without complex logistics. Cable-deployed setups meet these requirements by combining controlled positioning with continuous pumping and pipeline discharge. They are better suited to repetitive work in river mouths, approach channels, and terminal pockets where precision matters more than raw production volume.

At the same time, labour availability, safety requirements, and fuel costs are prompting operators to consider automation. Autonomous dredging, even in partial or assisted form, helps stabilise output by reducing manual intervention in pump control, depth management, and monitoring. This is not about removing crews entirely. It is about reducing variability in daily production and improving predictability over long maintenance cycles.

For contractors and port authorities in Pakistan, next-generation dredging is less about adopting new technology for its own sake. It is about choosing systems that align with how dredging work is actually executed today. Flexible deployment, controlled operating costs, and reliable slurry transport are now baseline requirements, not optional upgrades.

What Cable-Deployed Dredging Actually Looks Like in Pakistan Projects

On most projects in Pakistan, cable-deployed dredging is not a complex offshore operation. It is usually set up close to shore, along a jetty, or from a small pontoon positioned within the working channel. The dredge pump is lowered and positioned using winches and cables rather than a large self-propelled vessel. This approach keeps mobilisation simple and avoids the need for specialised marine assets.

A typical setup starts with anchoring points installed on shore or on temporary piles. These anchors control the lateral and longitudinal movement of the dredge head through steel cables. The pump, often a submersible or hydraulic dredge pump, is connected directly to a slurry pipeline that discharges material to a designated disposal area or settling pond. In many Pakistan waterways, this pipeline runs several hundred metres to a few kilometres, depending on site constraints.

Material removal is controlled by adjusting cable tension and pump depth rather than vessel movement. This allows operators to work accurately around berths, quay walls, intake structures, and narrow channel sections. In riverine environments, the system can be repositioned quickly as sediment patterns change after monsoon flows, without shutting down operations for days.

Slurry transport is where system reliability becomes critical. Continuous pumping places heavy wear on pipelines, especially when handling sand, silt, and mixed sediments common in Pakistan’s waterways. This is why abrasion-resistant slurry hoses and HDPE piping are typically used in cable-deployed dredging setups. Failures in this part of the system usually cause more downtime than the dredge pump itself.

From an operational perspective, cable-deployed dredging is better suited to maintenance work than to capital deepening. Production rates are steady rather than aggressive, but accuracy is higher. Depth targets can be maintained within tighter tolerances, reducing the need for repeated passes and corrective dredging.

For local contractors, this setup offers a practical balance. It avoids the high cost and regulatory complexity of large dredgers while delivering consistent results in shallow, constrained, or continuously silting areas. This is why cable dredging is increasingly being considered for routine maintenance projects across Pakistan’s waterways.

Cable-Deployed Dredging Compared with Conventional Dredging Methods Used Locally

Most dredging work in Pakistan still relies on a mix of mechanical dredgers, cutter suction dredgers, and occasionally trailing suction hopper dredgers for larger capital works. Each method has a role, but they are not equally effective for routine maintenance across Pakistan’s waterways.

Mechanical dredgers, such as backhoe or grab dredgers, are commonly used in confined areas. They are simple to deploy and familiar to local crews. However, production is intermittent rather than continuous. Material handling depends on barges, which introduces delays, weather sensitivity, and higher labour involvement. Depth accuracy also varies, especially when repeated passes are required near structures or quay walls.

Cutter suction dredgers are more productive and allow pipeline discharge, but they come with higher mobilisation costs and operational complexity. For smaller ports, river channels, and short maintenance campaigns, these dredgers are often oversized. Mobilisation time can exceed the actual dredging duration, which affects project economics.

Trailing suction hopper dredgers are effective for large-scale capital dredging but are rarely practical for routine maintenance in Pakistan’s waterways. They require deep access, specialised crews, and significant fuel consumption. Their use is generally limited to major port expansion or deepening projects.

Cable dredging sits between these extremes. It offers continuous pumping like cutter suction dredgers but without the need for a large self-propelled vessel. Because positioning is controlled by cables rather than vessel movement, the system works efficiently in narrow channels, shallow water, and near fixed infrastructure. Mobilisation is faster, and the footprint is smaller.

From a cost perspective, cable dredging reduces idle time. There are fewer support vessels, lower fuel consumption, and less crew exposure. For maintenance dredging, where volumes are moderate but frequency is high, this makes a measurable difference over time.

Accuracy is another key distinction. Conventional mechanical dredging often prioritises volume removal. Cable-deployed systems prioritise depth control. This reduces over-dredging and limits the need for corrective work, both common issues in local maintenance projects.

When automation is introduced, the gap widens further. Autonomous dredging functions such as pump control, depth monitoring, and production tracking are easier to integrate into cable-deployed systems than into traditional mechanical setups. Even partial automation improves consistency and reporting, which is increasingly important for contract compliance and environmental monitoring.

In practical terms, conventional dredging methods remain necessary for certain project types in Pakistan. However, for routine maintenance across Pakistan waterways, cable-deployed dredging offers a better balance of control, cost, and operational flexibility.

Choosing the Right Dredging Method for a Pakistan Project: a Procurement Perspective

For procurement teams, the dredging method is rarely a technical preference. It is a commercial decision shaped by budget cycles, mobilisation timelines, and long-term maintenance obligations. In Pakistan, these factors often matter more than peak production rates when selecting between conventional and cable-deployed dredging methods.

The first question is project frequency, not project size. One-time capital dredging may justify large cutter suction or hopper dredgers. Routine maintenance across Pakistan’s waterways does not. If dredging is required several times a year, faster mobilisation and lower daily operating costs become more important than maximum output. Cable dredging is typically better aligned with this requirement.

The second consideration is site constraint. Many local projects involve narrow channels, river sections, intake zones, or areas close to operational berths. Conventional dredgers need clearance, turning space, and support vessels. Cable-deployed systems operate within a smaller footprint and can be installed without disrupting port traffic to the same extent. From a procurement standpoint, this reduces indirect costs that are often not reflected in initial equipment pricing.

Disposal logistics also influence method selection. Projects that allow pipeline discharge to nearby settling areas favour pumping-based systems. Mechanical dredging introduces barging costs, scheduling delays, and additional crew requirements. When disposal distances are short to moderate, continuous slurry pumping becomes a more predictable and controllable option.

Equipment availability and support are other decisive factors. Procurement teams must assess not only the dredger itself but also pumps, pipelines, wear parts, and service response. Systems that rely on imported vessels with limited local support can increase downtime risk. This is where locally supported pumping systems, slurry hoses, and HDPE pipelines become commercially safer choices.

Automation readiness is increasingly a factor in procurement evaluations. While full autonomous dredging may not be immediately required, systems that allow remote monitoring, automated pump control, and production tracking offer better visibility and reporting. These features support contract compliance and help justify operating costs to stakeholders.

From a risk perspective, cable dredging reduces exposure. Lower fuel consumption, fewer moving marine assets, and simplified crew requirements all contribute to more predictable project execution. For procurement teams managing multiple sites across Pakistan’s waterways, this predictability is often the deciding factor.

Selecting the right dredging method is ultimately about alignment. The method must fit the frequency of work, the physical constraints of the site, and the availability of local technical support. In many Pakistan projects, cable dredging meets these criteria more consistently than conventional alternatives.

Case Example: Maintenance Dredging in a Constrained River Approach Channel

A mid-sized port facility on a tidal river section was facing recurring depth loss at its approach channel and berth pocket. Sedimentation increased sharply after each monsoon cycle, reducing available draft and forcing vessels to operate below optimal load. Previous maintenance relied on a small mechanical dredger supported by barges, but results were inconsistent, and re-dredging was required within months.

The project requirement was not capital deepening. It was predictable maintenance dredging that could be repeated several times a year without disrupting berth operations. Mobilisation time and operating cost were the main constraints.

The contractor adopted a cable dredging setup using a shore-based winch system and a submersible dredge pump. The dredge head was positioned using cable control rather than vessel movement, allowing work close to quay walls and within the narrow channel limits. Slurry was discharged through a continuous pipeline to a designated settling area located approximately 900 metres from the dredging zone.

Pipeline reliability was critical because shutdowns directly affected berth availability. Abrasion-resistant slurry hoses and HDPE piping were used for continuous operation under variable sediment conditions. Pump output and depth control were monitored remotely, allowing operators to maintain target levels with minimal adjustment. This also reduced over-dredging, which had been a cost issue in earlier campaigns.

The system was operated in multiple short dredging cycles rather than a single extended campaign. This approach aligned better with port traffic and reduced the need for emergency dredging after heavy siltation events. Fuel consumption and crew size were lower compared to previous methods, and production reporting was more consistent.

From a procurement standpoint, the project demonstrated why cable-deployed dredging is increasingly preferred for maintenance work across Pakistan’s waterways. The ability to mobilise quickly, operate within tight spaces, and rely on locally supported pumping and pipeline systems reduced both operational risk and total project cost.

The equipment package and system integration were supported locally by Hydro Pump and Dredge, including dredge pumps, slurry handling components, and Anaconda hose solutions suitable for repeated maintenance cycles. This local support proved as important as the dredging method itself.

Where Hydro Pump and Dredge Fit in Modern Cable-Deployed Dredging Projects

In Pakistan, the success of cable dredging often depends on more than the dredging method alone. It depends on whether the supporting equipment can be sourced, maintained, and replaced locally without interrupting operations. Pumps, pipelines, and wear components typically determine uptime more than the dredge head itself.

This is the operational space where the Hydro Pump and Dredge is positioned. Rather than supplying complete dredging vessels, the company focuses on the core systems that enable cable-deployed and semi-autonomous dredging to operate in local conditions. These include dredge pumps, slurry transport solutions, and pipeline systems that are designed for continuous duty rather than short campaigns.

For contractors working on Pakistan waterways, this distinction matters. Many projects rely on modular dredging setups assembled on site using available pontoons, winch systems, and pipelines. In these configurations, the reliability of pumps and slurry lines directly affects production. Failures typically occur in transport systems first, not cutting or positioning equipment.

Hydro Pump and Dredge supports these configurations by supplying abrasion-resistant slurry hoses, HDPE pipelines, and pumping systems that are commonly used in cable-deployed dredging layouts. Because these components are locally available and supported, procurement teams can plan maintenance dredging cycles without long lead times or dependency on overseas service calls.

The same applies as automation is gradually introduced. Autonomous dredging does not require entirely new dredgers in many cases. It often builds on existing pump-based systems through improved monitoring, control, and data visibility. Equipment that is already compatible with remote operation and continuous monitoring makes this transition smoother and less risky.

In practical terms, Hydro Pump and Dredge’s role is not to define how dredging should be done. It is to ensure that the pumping and slurry-handling systems used in cable-deployed dredging are robust enough to operate repeatedly across Pakistan’s waterways under real-world operating constraints. For many projects, this operational reliability is what determines whether a dredging strategy remains viable over time.

The Bottom Line

Dredging requirements across Pakistan’s waterways are increasing in frequency and operational complexity. In this environment, cable-deployed dredging offers a practical balance between control, cost, and flexibility for maintenance-focused projects. As automation and remote monitoring are gradually introduced, autonomous dredging is strengthening consistency rather than replacing existing methods.

The effectiveness of these approaches depends less on the dredging concept and more on the reliability of pumps, pipelines, and slurry handling systems that support continuous operation. Choosing equipment that can be sourced, serviced, and adapted locally remains a critical factor for long-term project viability.For contractors and port operators planning maintenance dredging on Pakistan waterways, Hydro Pump and Dredge provides locally supported dredge pumps, slurry hoses, and pipeline solutions suitable for cable-deployed and semi-autonomous dredging setups. Discuss your project requirements with the Hydro Pump and Dredge team to evaluate the right pumping and slurry transport configuration for your site.