Book Appointment Now

Durable Flooded Suction Pumps

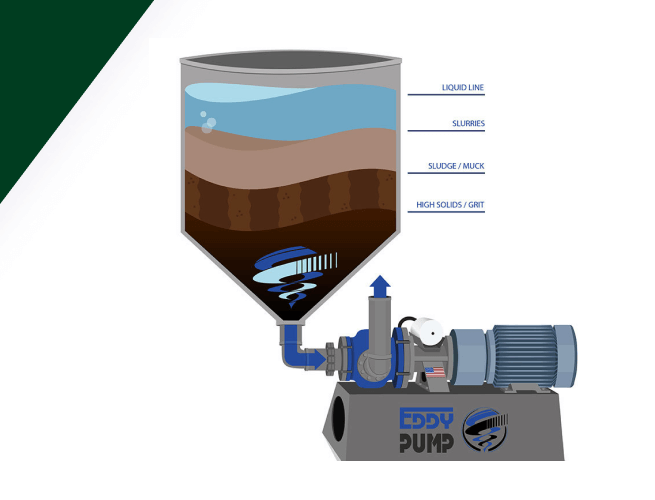

Hydro Pump and Dredge, the exclusive distributor of DAE Pumps in Pakistan, provides high-quality flooded suction pumps designed for tough industrial and dredging operations. These pumps, available in horizontal and vertical models, are built to handle demanding tasks with ease.

They are ideal for pumping thick, abrasive slurries, sludge, pastes, and high-solids materials, even when fluid levels are not steady. Their reliable performance makes them the perfect solution for challenging pumping jobs across various industries.

Designed for Strength and Reliability

These pumps are made with durability in mind, ensuring long-lasting and consistent operation. Whether you need to move thick, heavy fluids or deal with changing flow conditions, these pumps are built to handle it all.

These pumps are made with durability in mind, ensuring long-lasting and consistent operation. Whether you need to move thick, heavy fluids or deal with changing flow conditions, these pumps are built to handle it all.

If you’re looking for a dependable and efficient pump for your operations in Pakistan, Hydro Pump and Dredge is here to help. Contact us today to learn more or to request a quote for our flooded suction pumps.

Hydro Pump and Dredge

Cost-Effective and Efficient Pumping Solutions

Hydro Pump and Dredge, the exclusive distributor of EDDY Pump in Pakistan, offers one of the most dependable pumping technologies for demanding applications. Designed for efficiency, the EDDY Pump handles abrasive and viscous materials with ease, reducing the risk of clogging. Its low maintenance requirements make it a cost-effective solution for long-term use in various industries.

Unmatched Performance

EDDY Pump is renowned for its ability to handle high-flow and high-pressure applications across a wide range of sectors. Its advanced technology ensures superior performance, even in the most challenging pumping conditions.

Innovative Anti-Clogging Design

Engineered with an advanced anti-clogging system, the EDDY Pump prevents blockages even when dealing with large debris. This innovative feature improves operational efficiency and safety, minimizing downtime and maximizing productivity.

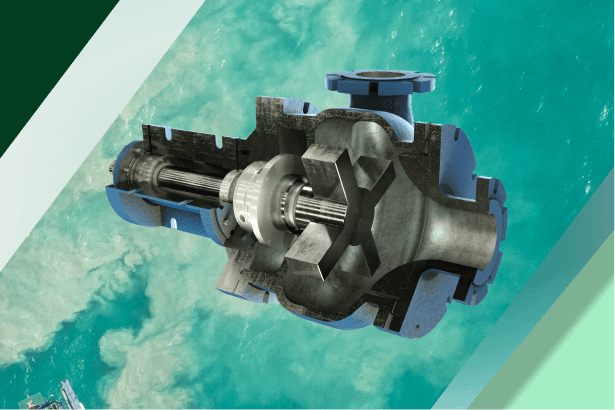

Built for Strength and Durability

Made with tough materials such as high chrome alloys, the EDDY Pump ensures long-lasting performance in demanding environments. Its robust construction guarantees reliability, making it a trusted choice for industries requiring durable and efficient pumping solutions.

Gravity-Assisted Pumping for Challenging Fluids

Flooded suction pumps are an ideal solution for industries like wastewater treatment, mining, and construction that require reliable handling of challenging fluids and sludge. By leveraging gravity to assist with fluid intake, these pumps provide efficient and consistent performance in demanding conditions.

The design positions the fluid above the pump’s inlet, allowing gravity to drive the liquid into the pump naturally. This eliminates the need for pre-priming, ensuring smooth, uninterrupted operation and reducing downtime.

With their ability to combine natural forces with advanced engineering, flooded suction pumps deliver cost-effective and efficient pumping solutions for even the most difficult applications.

Horizontal or Vertical Pumps: Which One is Right for You?

Selecting the right pump for your application depends on several key factors, including fluid density, flow rate, pressure, distance, power source, temperature, pH, and resistance to corrosion or erosion. Whether you choose a horizontal or vertical pump, opting for high-quality materials is essential for ensuring durability and a longer operational life.

Horizontal Flooded Suction Pumps

Flooded suction pumps are an ideal solution for industries like wastewater treatment, mining, and construction that require reliable handling of challenging fluids and sludge. By leveraging gravity to assist with fluid intake, these pumps provide efficient and consistent performance in demanding conditions.

The design positions the fluid above the pump’s inlet, allowing gravity to drive the liquid into the pump naturally. This eliminates the need for pre-priming, ensuring smooth, uninterrupted operation and reducing downtime.

With their ability to combine natural forces with advanced engineering, flooded suction pumps deliver cost-effective and efficient pumping solutions for even the most difficult applications.

Vertical Flooded Suction Pumps

Vertical flooded suction pumps are a versatile and efficient solution for applications requiring a compact design and reliable performance in confined or challenging spaces.

- Compact Size: With their space-saving design, these pumps are ideal for installations in tight or hard-to-reach areas, making them a practical choice for facilities with limited space.

- Highly Efficient: Designed for significant surface lift, vertical pumps excel in applications requiring the transfer of fluids from lower levels to higher elevations.

- Versatile Design: Vertical pumps can be suspended or inserted directly into the material being pumped, offering exceptional flexibility for various tasks.

- Maintenance Challenges: While effective, the design of vertical pumps may make repairs and routine maintenance more complex compared to horizontal options.

Advanced Semi-Automated Dredging System

The semi-automated dredge, available exclusively through Hydro Pump and Dredge, offers an innovative solution for efficient and precise dredging operations. This advanced system requires just 650 square feet of floor space, making it ideal for facilities with limited room. It operates with lower energy consumption and handles increased water depths without the need for onboard personnel, reducing operational costs and enhancing safety.

Key Features

- Cable-Controlled Navigation: The dredge utilizes three or four cables, guided by electronic winch controls, to navigate along a predefined dredging path with precision.

- Automated Adjustments: Operators can easily manage pump depth and RPM settings through advanced electronic instruments, ensuring optimal performance.

- Patented Cable Deployment System: Globestar’s unique system allows the dredge to function efficiently at depths of up to 100 feet, making it suitable for a variety of underwater environments.

- 24/7 Operation: With no internal structures to interrupt the flow, the dredge is capable of continuous operation, ensuring maximum productivity around the clock.

This cutting-edge system is designed for seamless and efficient dredging, providing a reliable solution for industries looking to enhance their operations.

Contact Hydro Pump and Dredge today to learn more about the semi-automated dredge and how it can transform your dredging projects in Pakistan.

Key Considerations for Selecting a Flooded Suction Pump

Pump Design

Look for a pump specifically designed for flooded suction applications. The pump should feature robust construction to handle challenging fluids like slurries, abrasives, or debris, ensuring dependable operation in demanding environments.

Performance Features

Flow Capacity

Flooded suction pumps should match your application’s required flow rate to ensure efficient operation. High flow rates are critical for handling large volumes of fluid in industrial applications.

Solids Handling Capability

These pumps excel in managing fluids with high solids concentrations, including slurry. They efficiently transport liquids containing particles, debris, or abrasive materials, making them ideal for heavy-duty applications.

Reduction of Obstructions

Engineered to allow solids to pass through without blockages, flooded suction pumps minimize downtime, maintenance, and repair needs, ensuring uninterrupted operation.

Enhanced Efficiency

By reducing the risk of clogging, these pumps maintain a steady flow, ensuring smooth and efficient pumping operations.

Increased Wear Resistance

Constructed from durable materials such as stainless steel, cast iron, or high-chrome alloys, flooded suction pumps offer superior wear resistance, extending their lifespan and operational reliability.

Cost-Effectiveness

Flooded suction pumps are a cost-effective choice for managing slurries and challenging fluids. Proper flow rate selection ensures optimized fluid handling, minimizing operational costs.

Technical Specifications

Head Pressure

Evaluate the pump’s ability to handle the required head pressure. This is critical for applications where fluid needs to be lifted vertically across significant distances.

Material Compatibility

Ensure the pump’s components are compatible with the fluid being pumped. For instance, corrosive fluids may require stainless steel, while abrasive materials might necessitate high-strength alloys.

Engine Power and Efficiency

Select a pump with a motor powerful enough to meet your flow and fluid density requirements. Efficient motors reduce energy consumption while maintaining performance.

Sealing Options

Reliable sealing options, such as mechanical seals or gland packing, are essential to prevent leaks and maintain performance, especially when handling abrasive or corrosive fluids.

Operational and Safety Features

Installation and Maintenance

Choose a pump that is easy to install and maintain. Accessibility for servicing and the availability of spare parts can significantly impact operational efficiency.

Security Features

Look for pumps equipped with safety features like overload protection, temperature sensors, and guards to prevent damage and extend the pump’s lifespan.

Manufacturer Reputation

Select a pump from a trusted manufacturer known for quality, reliability, and excellent customer service. A well-reputed manufacturer ensures that your pump meets industry standards and provides long-term support.

Key Advantages of Advanced Pump Technology

Advanced pump technology offers a range of benefits for industries managing challenging fluids, ensuring both efficiency and reliability in demanding applications.

Solids Handling Capability

These pumps are expertly designed to handle fluids with high solid content, such as slurries. They efficiently manage liquids containing particles, debris, or abrasive materials, making them ideal for tough industrial environments.

Reduced Risk of Obstruction

The advanced design minimizes the chances of clogging by allowing solids to pass through seamlessly. This feature significantly reduces downtime caused by maintenance or repairs, improving overall operational reliability.

Reduced Risk of Obstruction

The advanced design minimizes the chances of clogging by allowing solids to pass through seamlessly. This feature significantly reduces downtime caused by maintenance or repairs, improving overall operational reliability.

Boosted Efficiency

Flooded suction pumps are optimized for smooth operation, handling blockages effectively to ensure steady throughput. This leads to increased productivity and improved operational efficiency.

Enhanced Durability

Made from high-quality materials like stainless steel, high-chrome alloys, or cast iron, these pumps are built to withstand abrasive and corrosive fluids. Their robust construction ensures long-term performance with superior wear resistance.

Cost-Effective Fluid Handling

Flooded suction pumps offer a reliable and efficient solution at an affordable cost. Their ability to handle slurries and challenging fluids with minimal maintenance requirements makes them a valuable investment for industries needing durable and cost-effective equipment.

Our pump models

Model | Diameter | Power | GPM Flow | Head |

DSP/HD 3000 | 3 inches | 43 HP | 100 – 780 | up to 130 feet |

DSP/HD 4000 | 4 inches | 43 HP | 250 – 1200 | up to 200 feet |

DSP/HD 4000 | 4 inches | 115 HP | 250 – 1200 | up to 200 feet |

DSP/HD 6000 | 6 inches | 115 HP | 450-2000 | up to 200 feet |

DSP/HD 6000 | 6 inches | 173 HP | 450-2000 | up to 200 feet |

DSP 8000 | 8 inches | 550 HP | 1600 – 5000 | up to 240 feet |

DSP 10000 | 10 inches | 550 HP | 1600 – 5000 | up to 240 feet |

DSP 12000 | 12 inches | 700 HP | 2600 – 7300 | up to 180 feet |

Benefits of Managing Slurries and Complex Liquids

Self-Priming Capability

Self-priming pumps are designed to draw fluid without requiring additional priming components. This simplifies setup and operation, making the system more efficient and reducing assembly time.

Long-Lasting Durability

Equipped with advanced seals such as o-rings, mechanical seals, and durable liners, these pumps can withstand chemically or physically abrasive fluids. Their robust construction ensures consistent performance and a longer operational lifespan.

Versatile Applications

Submersible suction pumps are highly adaptable and capable of managing a wide variety of liquids, including high-solid-content fluids and sludge. These pumps are widely used in industries such as mining, construction, industrial processes, and water treatment.

Reduced Maintenance Requirements

Built with sturdy materials and a reliable design, these pumps require less frequent maintenance, lowering downtime and operational costs. Their efficiency ensures smooth performance over extended periods.

Consistent and Reliable Operation

Flooded suction pumps ensure a continuous fluid supply, preventing interruptions caused by air pockets or vibration issues. This steady operation enhances reliability and reduces the risk of equipment failure.

Related Equipment

Slurry Pumps

Discover our selection of slurry pumps designed for Pakistan’s industrial sector. These advanced pumps handle high-density mud, sand, and other abrasive materials with precision and strength. With innovative features for superior performance and durability, our pumps are ideal for even the most challenging projects.