Book Appointment Now

Advanced HDPE Pipe Solutions for Pakistan

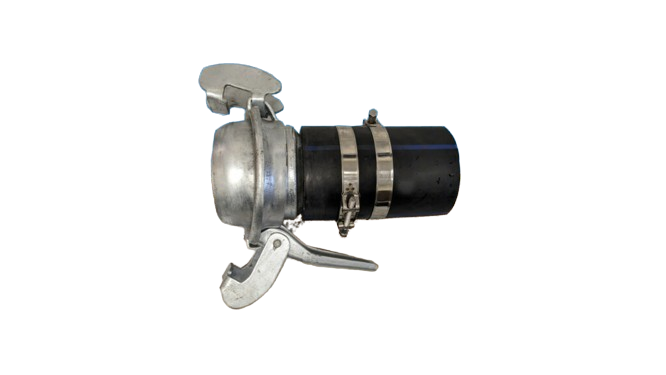

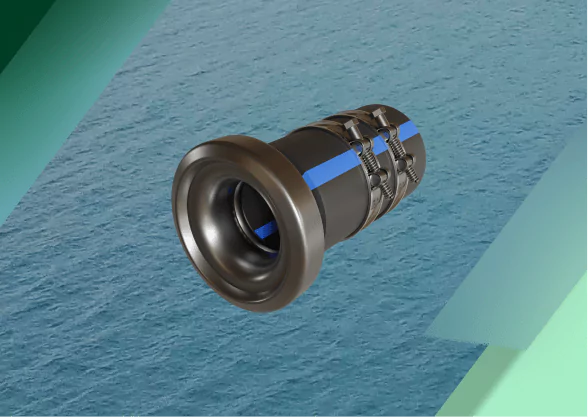

Innovative Bauer Couplings for Seamless Connections

Hydro Pump and Dredge offer Anaconda HDPE pipes equipped with robust and cost-effective Bauer couplings. These modular fittings simplify the process of connecting and disconnecting pipes, saving time and effort while enabling quick on-site adjustments for increased efficiency.

Versatile Thickness Options

Anaconda HDPE pipes are available in three key thickness categories: DR11, DR17, and DR26. This variety allows clients to select the perfect pipe thickness tailored to their specific project needs, ensuring optimal performance across diverse industrial applications.

Flexible Rental and Purchase Solutions

Hydro Pump and Dredge provides flexible rental and purchase plans for Anaconda HDPE pipes, making it easier for clients to manage costs. Short-term rental options are ideal for temporary projects, while purchase plans ensure long-term investment value.

Customized HDPE Pipes to Fit Your Needs

Anaconda Pipe and Hose ensures that every HDPE pipe can be customized to meet unique project requirements, including:

- Choice of diameter and length.

- Material composition.

- This customization guarantees that the pipes align perfectly with your industrial specifications.

Wide Application Versatility

Anaconda HDPE pipes are designed to excel in demanding environments. Whether it’s transporting liquids, managing chemicals, or supporting complex industrial fluid systems, their durable construction ensures reliable performance in even the most challenging conditions.

Compatible Fittings for Leak-Proof Systems

Engineered for adaptability, Anaconda HDPE pipes are fully compatible with various fittings, including threaded connections, Bauer couplings, ANSI flanges, and more. This ensures a secure and leak-proof installation every time.

As the exclusive distributor in Pakistan, Hydro Pump and Dredge proudly deliver Anaconda Pipe and Hose’s cutting-edge HDPE pipe solutions. With a commitment to reliability and innovation, we provide the perfect solutions to meet the demands of your industrial projects.

Hydro Pump and Dredge

Simplify Your Piping System with Ease

Discover the advantages of seamless HDPE pipes in straight lengths—no fittings required. Enjoy enhanced flow efficiency, reduced maintenance costs, and quick, hassle-free installation. Let our experts guide you in choosing the perfect HDPE solution tailored to your project needs.

Contact us now to learn more about how our HDPE pipes can elevate your system’s performance and reliability.

Engineered for Industrial Precision

Hydro Pump and Dredge’s industrial HDPE pipes are designed to meet the rigorous demands of challenging industrial environments. Featuring versatile Bauer fittings, these pipes allow for seamless connection and disconnection, offering unmatched modularity to adapt swiftly to changing project needs. Manufactured from premium-grade materials, they endure high pressure and extreme temperatures with ease. Their advanced protective coatings provide exceptional corrosion resistance, extending their operational lifespan even in the most corrosive conditions.

With precise dimensional accuracy, these HDPE pipes integrate flawlessly with a variety of fittings, minimizing the risk of leaks and ensuring reliable performance. They strike a perfect balance between flexibility for adaptable installations and rigidity to maintain strength under operational pressures.

Every pipe undergoes rigorous quality testing and adheres to industry standards, ensuring long-lasting reliability. Hydro Pump and Dredge are committed to delivering high-performance HDPE piping solutions tailored to meet the diverse and complex requirements of industrial projects.

Optimizing Industrial Pipe Systems with Bauer Fittings

Bauer fittings, renowned for their quick-connect functionality, have become essential in industrial pipe systems across sectors such as wastewater management, irrigation, construction, and mining. Also known as Bauer Couplings, these fittings ensure fast, secure connections that minimize downtime while enhancing system reliability and environmental protection through leak-proof operations.

One of their most impressive features is their adaptability. Bauer fittings effortlessly accommodate various pipe materials and sizes, making them a versatile choice for diverse fluid transport applications. Constructed from durable materials like high-grade galvanized or stainless steel, they are engineered to endure tough industrial conditions, extending service life and reducing the need for frequent replacements. Their efficient sealing system ensures a leak-free connection, even when handling corrosive chemicals or abrasive slurries, while their pressure flexibility broadens their scope of use across varying pressure levels.

Designed with ease of use in mind, Bauer fittings feature a quick-locking mechanism that simplifies operation and boosts efficiency in managing pipe systems. Their compatibility with different brands and materials eliminates the need for complex processes such as pipe fusing or welding, streamlining maintenance, and repairs. Combined with low maintenance requirements and cost-effectiveness, these features make Bauer fittings an excellent solution for companies seeking to optimize fluid handling operations.

Additionally, Bauer fittings offer a wide range of accessories, enabling greater customization and functionality to meet the unique demands of industrial applications. This adaptability, paired with their proven reliability, positions Bauer Fittings as a trusted choice for fluid management in challenging environments.

The Benefits of Straight Lengths of HDPE Pipes Without Fittings

In industrial operations, opting for straight lengths of HDPE pipes without fittings presents several significant advantages, both operational and technical. By eliminating fittings, these configurations create a smoother, uninterrupted flow path, reducing friction and turbulence. This improvement in flow dynamics enhances overall system efficiency, making it a preferred choice for applications where consistent and optimized fluid transport is crucial.

Straight lengths of HDPE pipes simplify installation and maintenance processes. With fewer components, the risk of wear and failure decreases, leading to reduced maintenance needs and lower long-term costs. Installation becomes more straightforward as straight pipes are easier to handle, align, and connect, which can save significant time and labor, particularly in large-scale projects.

The continuous design of straight pipe lengths also bolsters pipeline structural integrity. This is especially critical in environments where external forces or stability concerns are prevalent. Fewer connections mean fewer potential leak points, a crucial factor in systems handling hazardous or sensitive materials where leak prevention is paramount.

From a cost perspective, straight HDPE pipes without fittings can provide considerable savings. When fittings are not necessary due to the nature of the fluid, pressure conditions, or other system requirements, the savings in materials and labor can be substantial. This makes it a cost-effective option for many industrial applications.

However, it’s important to assess whether this setup suits the specific demands of a project. For systems requiring frequent connections or adjustments, fittings like Bauer or ANSI may offer better flexibility and convenience. Consulting with engineering professionals and adhering to industry standards is essential to ensure the chosen piping configuration aligns with the application’s unique requirements.

Related Equipment

Pipes and Hoses

Our selection of durable pipes and hoses is engineered to withstand Pakistan’s toughest environments. Available in various sizes and configurations, our products handle abrasive and corrosive fluids effectively, providing reliable fluid transportation solutions for both industrial and commercial needs.