Book Appointment Now

Optimized Apex Filter Press Pumps with Advanced VFD Control

Apex Filter Press Pumps are designed to provide unmatched precision and efficiency, seamlessly integrating with a wide range of filter press sizes. Equipped with advanced Variable Frequency Drive (VFD) technology, these pumps deliver superior operational control, starting with variable speed operation to suit the unique demands of filtration processes.

Enhanced Filtration with Smart Pressure Control

The Apex pumps initiate the filtration cycle with high flow rates and low pressure, ensuring the gradual formation of the filter cake. This critical phase prevents premature clogging of the filter cloth by avoiding the rapid buildup of a dense, impermeable solids layer.

As the filtration progresses, the VFD technology automatically increases the feed pressure in controlled increments, adapting to the specific slurry characteristics and solids concentration. This gradual pressure escalation ensures optimal filtration efficiency while reducing wear on the system.

Precise Operation for Maximum Efficiency

The pumping process typically begins at a low pressure of around 25 PSI and gradually increases to a shut-off pressure of approximately 100 PSI, depending on the filter press’s requirements. The pump automatically shuts off when the desired pressure is reached, ensuring precision and efficiency throughout the filtration cycle.

Key Benefits of Apex Filter Press Pumps

- Enhanced Efficiency: VFD control optimizes pressure adjustments for maximum filtration performance.

- Extended Equipment Life: Prevents premature clogging of filter cloths, reducing maintenance costs and downtime.

- Versatile Integration: Compatible with both new and existing filter press setups, ensuring easy installation and seamless operations.

- Customizable Control: Pressure and flow adjustments tailored to specific industrial requirements.

With advanced VFD technology, Apex Filter Press Pumps offers a flexible and reliable solution to improve the efficiency and longevity of industrial filtration processes. Contact us today to learn how these pumps can revolutionize your filter press operations

Hydro Pump and Dredge

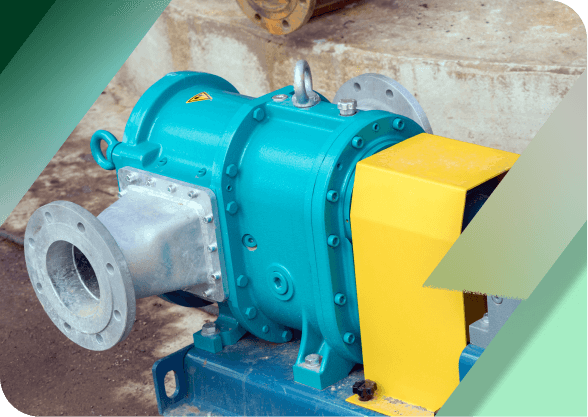

Unmatched Durability for Managing Abrasive Liquids

Handling abrasive liquids with suspended particles can rapidly degrade traditional pumps, resulting in reduced efficiency and frequent maintenance. Hydro Pump and Dredge, the trusted distributor of advanced pumping solutions in Pakistan, addresses this challenge with the Apex rotating disk pump, designed for superior durability and reliability.

The innovative Apex rotating disk pump directs fluid flow between two parallel disks, creating a stable boundary layer—a calm layer of fluid near the disk walls. This design minimizes abrupt directional changes and rapid accelerations, reducing wear and tear on internal components and significantly enhancing abrasion resistance.

By maintaining the integrity of the boundary layer, the Apex pump ensures exceptional performance and reliability when handling abrasive slurries. Built for long-lasting operation, it reduces maintenance needs and minimizes downtime, making it a cost-effective solution for demanding industries.

Hydro Pump and Dredge provide this advanced pump to meet the rigorous needs of mining, construction, and wastewater applications in Pakistan. Contact us today to discover how the Apex rotating disk pump can optimize your operations.

Low NPSH Requirement for Enhanced Performance

In demanding environments like those found in Pakistan, pumps often face challenges from variable pressure distribution caused by impeller vanes moving through fluids, increasing the risk of cavitation. Cavitation typically occurs at the point of lowest static pressure, usually near the vane outlet. The Apex Disk Pump, available through Hydro Pump and Dredge, effectively addresses this issue with disk impellers designed for inherently low Net Positive Suction Head Required (NPSHR) characteristics. Additionally, the pump features an integral axial flow inducer, further optimizing its low NPSH capabilities and making it a durable solution for challenging applications.

The Apex Disk Pump is engineered to create a uniformly tangential pressure field throughout the system, ensuring the presence of only positive pressure gradients. This uniform pressure distribution is critical for maintaining efficiency and longevity, particularly in harsh operational conditions commonly encountered in Pakistan.

Optimized Performance with Highly Viscous Liquids

Handling highly viscous liquids presents significant challenges for traditional vaned impellers, often resulting in reduced efficiency, decreased capacity, and increased NPSH requirements. Fluids with viscosities of approximately 500 SSU can drastically impair the performance of conventional pumps.

The Apex Disk Pump overcomes these challenges with a unique design that includes carefully optimized disk spacing, allowing it to manage a wide range of fluid viscosities effectively. Whether handling water-like fluids or substances as viscous as 400,000 SSU, the Apex Disk Pump demonstrates remarkable adaptability, making it an ideal choice for various industrial applications.

Its design ensures the pump’s flow characteristics adjust according to the fluid’s viscosity, maintaining marginal turbulence for thinner liquids and transitioning to laminar flow for more viscous substances. This flexibility enhances the pump’s efficiency and ensures consistent, reliable performance across a broad spectrum of fluid densities and viscosities, making it indispensable for industries requiring versatile and robust pumping solutions.

Related Equipment

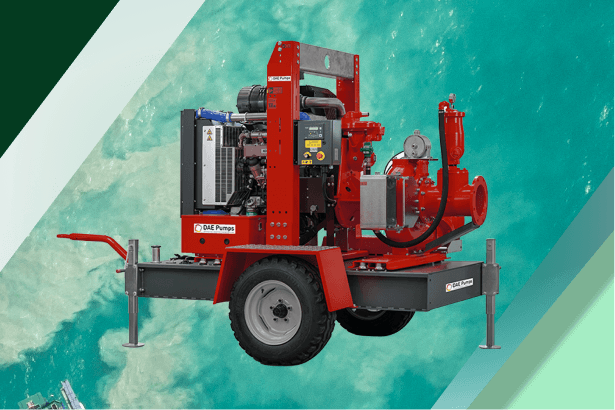

Dewatering Pumps

Browse our range of dewatering pumps, perfect for applications in Pakistan like irrigation, fountains, and liquid transfer. Known for their reliability and cost-efficiency, these pumps offer smooth operation across various scenarios, meeting both small-scale and large-industrial needs.